TUBING/HOSES

【SHPI Professional Guide】Industrial Tubing Guide

In today's highly competitive industrial automation market, every component matters. When pneumatic or fluid transfer tubing fails, it can cause costly downtime, rising maintenance expenses, and even safety risks.

As one of the largest tubing manufacturers in Taiwan, SHPI is your trusted partner. We understand that professional purchasers value quality, reliability and compliance with international standards. This guide helps you choose the most efficient and reliable tubing solutions for automation, automotive, semiconductor, mechanical equipment and food processing industries.

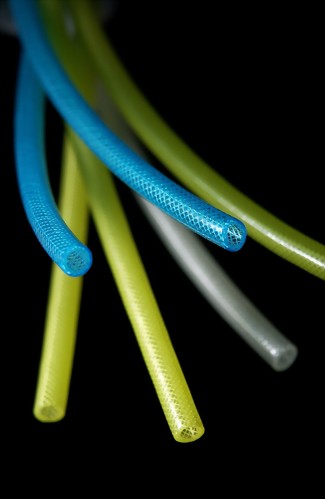

Core Product Lines: Select by Material & Form

Lightweight, flexible, abrasion-resistant.

Ester-based Best for dry, standard industrial environments.

Ether-based FDA-compliant, hydrolysis-resistant, antimicrobial — ideal for humid, outdoor and food-processing environments.

High tensile strength, excellent pressure and chemical resistance.

Nylon 6 High rigidity, suitable for high-pressure dry environments such as CNC machines.

Nylon 12 Low moisture absorption, abrasion-resistant, UV- and chemical-resistant, FDA compliant — ideal for semiconductors, automotive and outdoor use.

Excellent chemical stability. Commonly used in drinking water, food processing, chemical fluids and cooling water systems.

Outer cover meets UL94 V-0 flame resistance, effectively blocking sparks. Designed for high-spark industrial environments to reduce fire hazards.

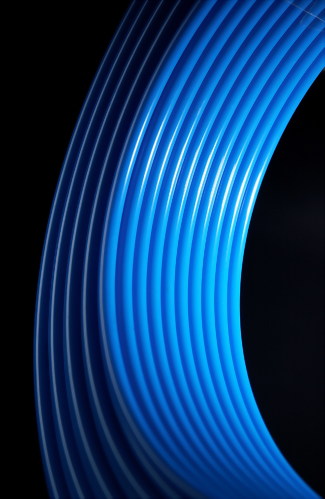

Fiber-braided construction, pressure resistant up to 300 PSI. Lightweight and flexible — perfect for industrial pipelines and pneumatic tools.

Maintains flexibility in low temperatures, kink-free with no memory effect and strong pressure resistance. Perfect for outdoor and extreme weather conditions.

Unique elastic memory allows automatic retraction, saving working space and decreasing tripping hazards.

Available in PU, reinforced PU, and Nylon 12 options for industrial and chemical-resistant needs.

A critical core component for medium and heavy-duty commercial vehicles. SHPI's air brake tubing complies with SAE J844 and DIN 74324 standards to ensure braking safety and reliability.

Designed for trucks and trailers, offering excellent elasticity and durability. Fully compliant with SAE J844 and DIN 74323 requirements, supporting dynamic movement between tractor and trailer.

Five Reasons to Choose SHPI

Looking for reliable industrial tubing?

Contact our team today to request catalogs, free samples, and quotations.