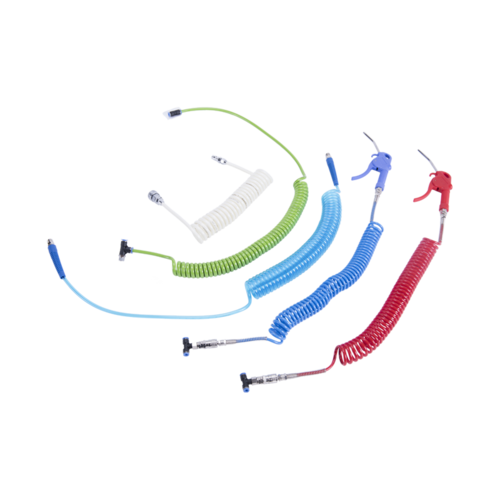

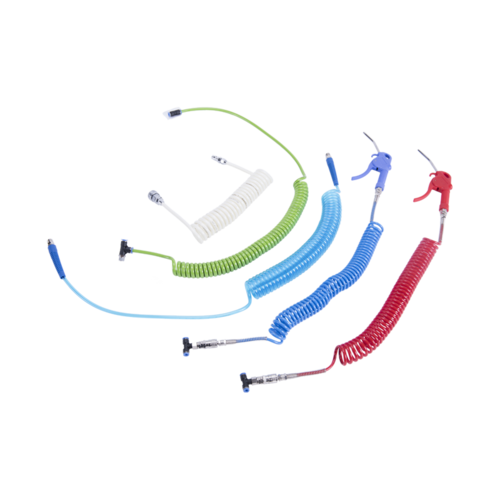

Coiled Air Hose

Coiled Hose Selection Guide | PU, Nylon & High-Pressure Spiral Hose

In factories, automotive repair shops and automotive production lines, tangled pneumatic hoses not only reduce efficiency but also increase the risk of tripping and safety hazards. A coiled hose, with its unique elastic memory, helps keep the workspace organized and clutter-free. The design ensures efficiency, safety, and compliance in demanding environments such as auto maintenance, CNC machining, and food processing.

SHPI has developed four major coiled hose series to meet diverse B2B requirements. Each series is engineered to deliver reliable performance in demanding applications.

SHPI Coiled Hose Series: Industrial, food-grade and High-pressure solutions

PU Coiled Hose – Imperial (U.S. Standard)

| Advantages | Applications |

|---|---|

|

– Lightweight, highly elastic, and anti-microbial. – Designed for the U.S. market, following the imperial system. – Made from FDA-compliant material, guaranteeing fluid purity and safety. |

– Widely used in automotive production, CNC machining, and tool maintenance for pneumatic tool supply. – FDA compliance also makes it ideal for food processing and packaging industries. |

PU Coiled Hose – Metric (Europe & Asia)

| Advantages | Applications |

|---|---|

|

– Tailored for pneumatic systems in Europe and Asia, designed according to the metric system. – Excellent elasticity and durability. |

– Widely used in automotive production, CNC machining, and tool maintenance for pneumatic tool supply. – FDA compliance also makes it ideal for food processing and packaging industries. |

High-Pressure Polyurethane Spiral Hose

| Advantages | Applications |

|---|---|

|

– Features a triple-layer construction. – Capable of withstanding up to 300 PSI working pressure—far exceeding standard coiled hose ratings. |

– Ideal for high-pressure pneumatic tools, large-scale air compressors, and heavy-duty equipment. |

Nylon 12 Coil Hose

| Advantages | Applications |

|---|---|

|

– Superior chemical resistance, capable of withstanding most chemicals, fuels and lubricants. – Outstanding weather resistance, delivering consistent performance in extreme conditions. |

– A perfect choice for the automotive industry, machining and laboratory applications, both indoors and outdoors. – Manufactured with FDA-compliant materials, making it suitable for food processing and packaging. |

Four Key factors in choosing coiled hose

✅ Working environment:

Determine whether abrasion resistance, chemical resistance or cleanliness standards are essential.

✅ Flow and pressure:

How much working flow and pressure does your equipment need? SHPI coiled polyurethane hose covers applications from light to high-pressure demands of 300 PSI, ensuring both safety and efficiency.

✅ Effective Length:

SHPI specifications always indicate the working length, which is the maximum usable length without overstretching. This is one of the most critical elements when choosing a coiled hose.

✅ Environmental regulation:

For companies focusing on ESG, REACH and RoHS compliance are critical requirements when sourcing coiled polyurethane tubing.

The five core advantages to choose SHPI

✅ 100% Made in Taiwan Quality Assurance:

Every coiled hose is 100% made in Taiwan, ensuring consistent quality and rigorous manufacturing standards.

✅ Versatile Fitting Options:

SHPI provides a wide variety of fitting assemblies. Simply refer to the “Fitting Selection Guide” to customize combinations and meet all your requirements in one stop.

✅ Visual Management:

Multiple color options allow quick recognition by different colors, increasing safety and efficiency.

✅ Extensive OEM/ODM Capabilities:

Fast project response and customized solutions tailored to your needs.

✅ Professional Support:

We not only provide high-quality products but also deliver comprehensive technical consulting and support services.

Choose SHPI means choosing quality and commitment.

Contact our professional team today to discover the best coiled hose solutions for your pneumatic systems.

Coiled Polyurethane Air Hose Assembly -Metric System

ㆍPolyurethane recoil tubing for general pneumatic line connections

ㆍTubing returns to its original form after extension

Coiled Polyurethane Air Hose Assembly -Imperial System

ㆍPolyurethane recoil tubing for general pneumatic line connections

ㆍTubing returns to its original form after extension

Coiled Reinforced Polyurethane Air Hose Assemblies

ㆍPolyurethane braided coiled hose construction

ㆍSpiral-formed design for pneumatic system line connections

ㆍCoiled form with shape recovery after extension

Coiled Nylon Air Hose Assemblies PA 12

• Nylon 12 material coiled tubing structure

• Coiled design for pneumatic line connections in general air systems

• Tubing returns to its original form after extension