Japanese System Couplers & Plugs

Selection Guide: Japanese System Couplers & Plugs

Engineered for maximum operational stability and safety, the Japanese System is a premier quick-connect standard designed for long-term reliability in demanding industrial environments.

As a highly mature and versatile standard, it is the primary pneumatic interface across Taiwan, Japan, South Korea, China, and Southeast Asia. It is also the dominant coupling profile in Australia and New Zealand, with a rapidly growing footprint in Brazil, India, and the Middle East.

▼ Collapse the Guide ↩

Japanese System Quick Selection Matrix

Find the right solution at a glance without complex decision-making.

Standard Series (1/4” Body)

| Type | Coupler Model | Operation | Description | Matching Plug |

|---|---|---|---|---|

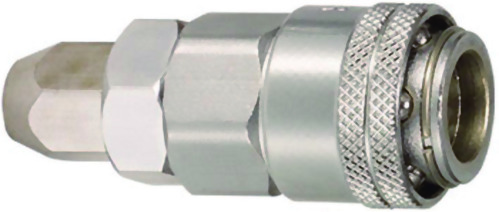

| Traditional | NC | Two-Touch | Standard dual-stage structure; ensures stability and durability. | NP |

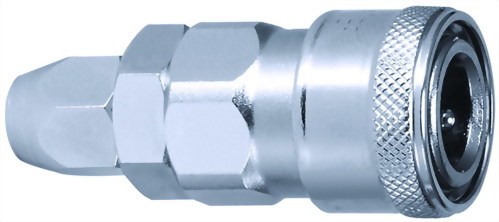

| Single-Hand | NOC | One-Touch | Single-handed operation; ideal for high-frequency tool changes. | NP |

| Single-Hand PLUS | NSC | One-Touch | Enhanced safety with a combined One-Touch, Swivel, and Lock design. | NP |

High-Flow Series

| Type | Coupler Model | Operation | Description | Matching Plug |

|---|---|---|---|---|

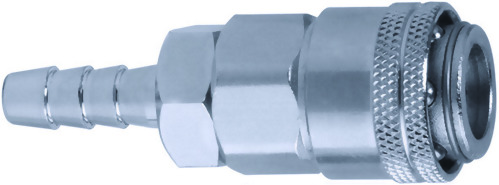

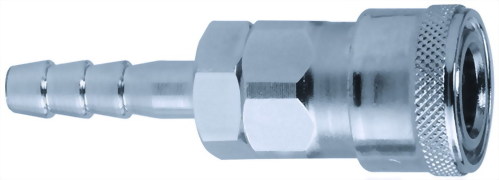

| High-Flow | NLC | Two-Touch | Enlarged body and bore size for high-volume pneumatic transmission. | NLP |

Japanese System FAQ

Q1: One-Touch vs. Two-Touch?

- One-Touch (Speed): Preferred in Japan, Australia, & NZ for rapid operation.

-

Two-Touch (Safety): Preferred in SE Asia for maximum structural stability.

Note: These differences are a result of practical application and regional safety habits rather than technical limitations.

Q2: Why is the High-Flow (NLC) series Two-Touch only?

Safety First: To handle the increased back-pressure thrust. The two-stage disconnection helps prevent accidental blow-outs and supports industrial safety under high-flow conditions.

Q3: Heat Treatment (Durability)

- NP Series Plugs: Heat-treated to withstand high-frequency friction and extend service life.

-

NLP Series Plugs: Optimized for air-flow path; heat treatment is not required.

Q4: Can Couplers be heat-treated?

No. Couplers are precision assemblies. Heat treatment may deform internal springs and seals, compromising airtight performance and operational stability.

Expert Consulting & OEM Services

For personalized selection advice, application consulting, or high-volume OEM/Private Labeling, please contact the SHPI Team. We are dedicated to helping you find the most efficient coupling solution for your pneumatic system.