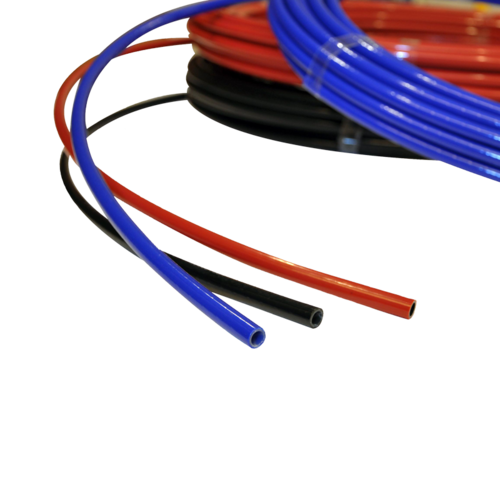

Air Brake Hose

High-Quality Air Brake Tubing | DIN 74324 & SAE J844 Certified | DOT Approved

What is an Air Brake Tubing System?

The Core of Braking for Your Trucks, Buses, and Semi-Trailers

Air brake tubing is a core safety component for large commercial vehicles such as trucks, trailers, buses, and semi-trailers. When the driver presses the brake pedal, the brake assist system activates, utilizing high-efficiency pneumatic technology to enhance braking performance. This allows the driver to achieve optimal braking effect with less effort, thereby improving overall driving safety. Therefore, air brake tubing has become a global standard installation to ensure the safe operation of heavy-duty vehicles. Moreover, the reliability and safety of the entire braking system depends on the quality of tubing and its compliance with international standards.International Standards: DIN 74324 & SAE J844

SHPI specializes in manufacturing air brake tubing that strictly complies with two major international standards, offering specifications that meet these requirements:

• DIN 74324:This German standard is widely used and recognized across the European market for air braking systems and other applications in motor vehicles. It sets strict requirements for tubing dimensions (6mm~18mm), materials, pressure resistance, flame retardance, and operating temperature ranges. Air brake tubing that meets DIN 74324 standard offers excellent corrosion resistance and long-term durability, ensuring the highest level of safety and quality even under various harsh weather and road conditions.

• SAE J844:

SAE J844 is established by the Society of Automotive Engineers (SAE) in the United States. The standard targets non-metallic air brake system tubing specifically designed for heavy-duty vehicles. It defines air brake tube sizes ranging from 1/8”to 3/4” and classifies them into Type A and Type B.

Type A: Intended for use in locations where the tubing is protected by the vehicle structure.

Type B: Intended for use in exposed locations where the tubing is subjected to sunlight, ozone, oil, gasoline, battery acid, or mechanical damage. Coiled tubing used in tractor-trailer applications shall meet the requirements for Type B.

These classifications ensure tubing is properly selected for different parts of the vehicle. All tubing must meet rigorous performance requirements to withstand severe climates and extreme temperature variations, maintaining superb flexibility, reliability, and robust braking safety under harsh conditions.Advantages of Choosing SHPI Air Brake Tubing

-

DOT Approved

- Compliance with international standards and regulations

- Excellent environmental resistance

- High-quality materials and rigorous manufacturing processes

- Extensive customization and OEM services

- Competitive cost-performance and global delivery capabilities

Contact us today to find the DOT tubing that best fits your needs.

Air Brake Tubing DIN 74324

・Tubing for pneumatic air brake systems

DOT Air Brake Tubing SAE J844

・Air brake tubing for automotive and commercial vehicle systems

・Designed in accordance with SAE J844 engineering specification (North America)

・DOT FMVSS 571.106 (FMVSS 106) compliant versions available, supported by verified test compliance