Anti-Spark Tubing

※ Click the product image to view more specs and technical details.

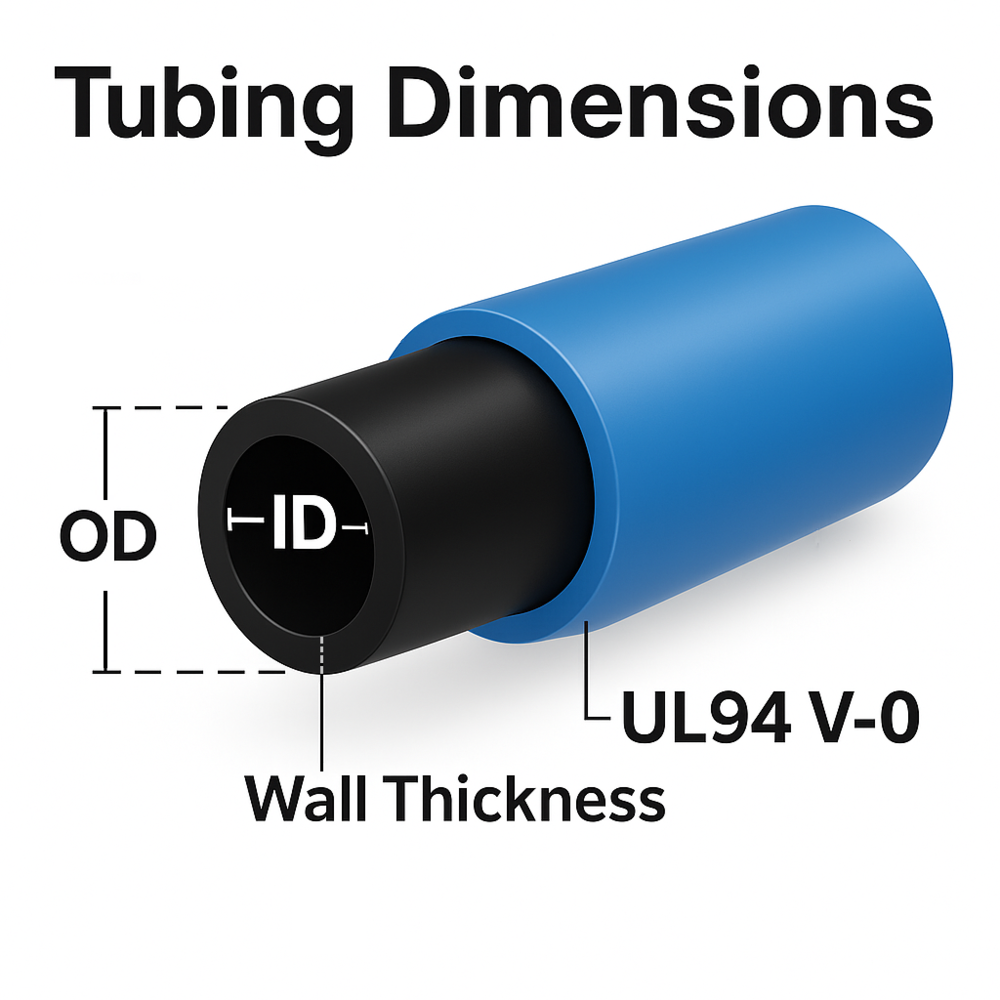

ㆍDual-layer construction: PU inner tubing combined with an outer flame-retardant layer

ㆍOuter layer material classified to UL 94 V-0 flammability rating with self-extinguishing characteristics

ㆍStructural design intended for tubing surface protection in environments involving welding sparks, spatter, and similar operations

ㆍPU tubing maintains the flexibility and dynamic bending stability required for pneumatic routing

ㆍDual-layer construction: PU inner tubing combined with an outer flame-retardant layer

ㆍOuter layer material classified to UL 94 V-0 flammability rating with self-extinguishing characteristics

ㆍStructural design intended for tubing surface protection in environments involving welding sparks, spatter, and similar operations

ㆍPU tubing maintains the flexibility and dynamic bending stability required for pneumatic routing

Model :

DAS

An integrated dual-layer tubing construction, using polyurethane (PU) as the inner tubing for compressed air conveyance in pneumatic systems, and incorporating an outer flame-retardant material design. This structure provides additional surface protection when the tubing is exposed to incidental contact with welding sparks or spatter in welding and fabrication environments.

The outer flame-retardant layer meets the UL 94 V-0 flammability classification and exhibits self-extinguishing behavior, defining the tubing's flammability performance under short-term contact with sparks or high-temperature sources.

The outer flame-retardant layer meets the UL 94 V-0 flammability classification and exhibits self-extinguishing behavior, defining the tubing's flammability performance under short-term contact with sparks or high-temperature sources.

Available in inch and mm sizes

Imperial Size (inch)

|

Model Number

|

Inner Tube OD | Inner Tube ID | Inner Tube Wall Thickness | Jacket Thickness | Max. Working Pressure 73°F | Min. Bend Radius | Packing Length | Color | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| +Color | inch | inch | inch | inch | psi | inch | ft | BU | GY | R | Y | W |

| DAS14156100FT_ | 1/4 | 0.156 | 0.05 | 0.04 | 180 | 0.59 | 100 | ■ | ■ | ■ | ■ | □ |

| DAS14156250FT_ | 250 | |||||||||||

| DAS516196100FT_ | 5/16 | 0.196 | 0.06 | 0.04 | 175 | 0.78 | 100 | ■ | ■ | ■ | ■ | □ |

| DAS516196250FT_ | 250 | |||||||||||

| DAS38250100FT_ | 3/8 | 0.250 | 0.06 | 0.04 | 150 | 0.98 | 100 | ■ | ■ | ■ | ■ | □ |

| DAS38250250FT_ | 250 | |||||||||||

| DAS12328100FT_ | 1/2 | 0.328 | 0.09 | 0.04 | 150 | 1.17 | 100 | ■ | ■ | ■ | ■ | □ |

| DAS12328250FT_ | 250 | |||||||||||

Metric Size (mm)

|

Model Number

|

Inner Tube OD | Inner Tube ID | Inner Tube Wall Thickness | Jacket Thickness | Max. Working Pressure 23°C (73°F) | Min. Bend Radius | Packing Length | Color | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| +Color | mm | mm | mm | mm | bar | mm | m | BU | GY | R | Y | W |

| DAS604025M_ | 6.0 | 4.0 | 1.00 | 1.0 | 12 | 15 | 25 | ■ | ■ | ■ | ■ | □ |

| DAS604050M_ | 50 | |||||||||||

| DAS805025M_ | 8.0 | 5.0 | 1.50 | 1.0 | 12 | 20 | 25 | ■ | ■ | ■ | ■ | □ |

| DAS805050M_ | 50 | |||||||||||

| DAS106525M_ | 10.0 | 6.5 | 1.75 | 1.0 | 10 | 25 | 25 | ■ | ■ | ■ | ■ | □ |

| DAS106550M_ | 50 | |||||||||||

| DAS128025M_ | 12.0 | 8.0 | 2.00 | 1.0 | 10 | 30 | 25 | ■ | ■ | ■ | ■ | □ |

| DAS128050M_ | 50 | |||||||||||

ㆍOuter flame-retardant material layer for tubing surface protection

ㆍUL 94 V-0 flammability classification with self-extinguishing characteristics (outer layer)

ㆍPU inner tubing suitable for compressed air and pneumatic system conveyance

ㆍPU tubing flexibility and dynamic bending stability for pneumatic routing

ㆍUL 94 V-0 flammability classification with self-extinguishing characteristics (outer layer)

ㆍPU inner tubing suitable for compressed air and pneumatic system conveyance

ㆍPU tubing flexibility and dynamic bending stability for pneumatic routing

ㆍPneumatic tubing systems installed around welding processes

ㆍAir supply and pneumatic routing near welding stations, fixtures, or robotic arms

ㆍOperating environments where external sparks or short-duration high-temperature sources may contact the tubing surface

ㆍTubing areas in metal processing, grinding, or assembly lines where incidental spark or heat exposure should be considered

ㆍAir supply and pneumatic routing near welding stations, fixtures, or robotic arms

ㆍOperating environments where external sparks or short-duration high-temperature sources may contact the tubing surface

ㆍTubing areas in metal processing, grinding, or assembly lines where incidental spark or heat exposure should be considered