Nylon Tubing PA 6

ㆍGood mechanical strength and rigidity

ㆍStable chemical compatibility with commonly used industrial oils and media

ㆍConsistent mechanical performance

ㆍGood abrasion resistance

Nylon 6 (PA6) is a commonly used polyamide material with good mechanical strength and rigidity for industrial pneumatic and fluid conveying systems.

Based on the material characteristics, SHPI applies standardized process control conditions to maintain stable mechanical performance during operation. PA6 tubing is suitable for applications operating under relatively stable environmental conditions (such as humidity or temperature).

Imperial Size (in)

|

Part Number

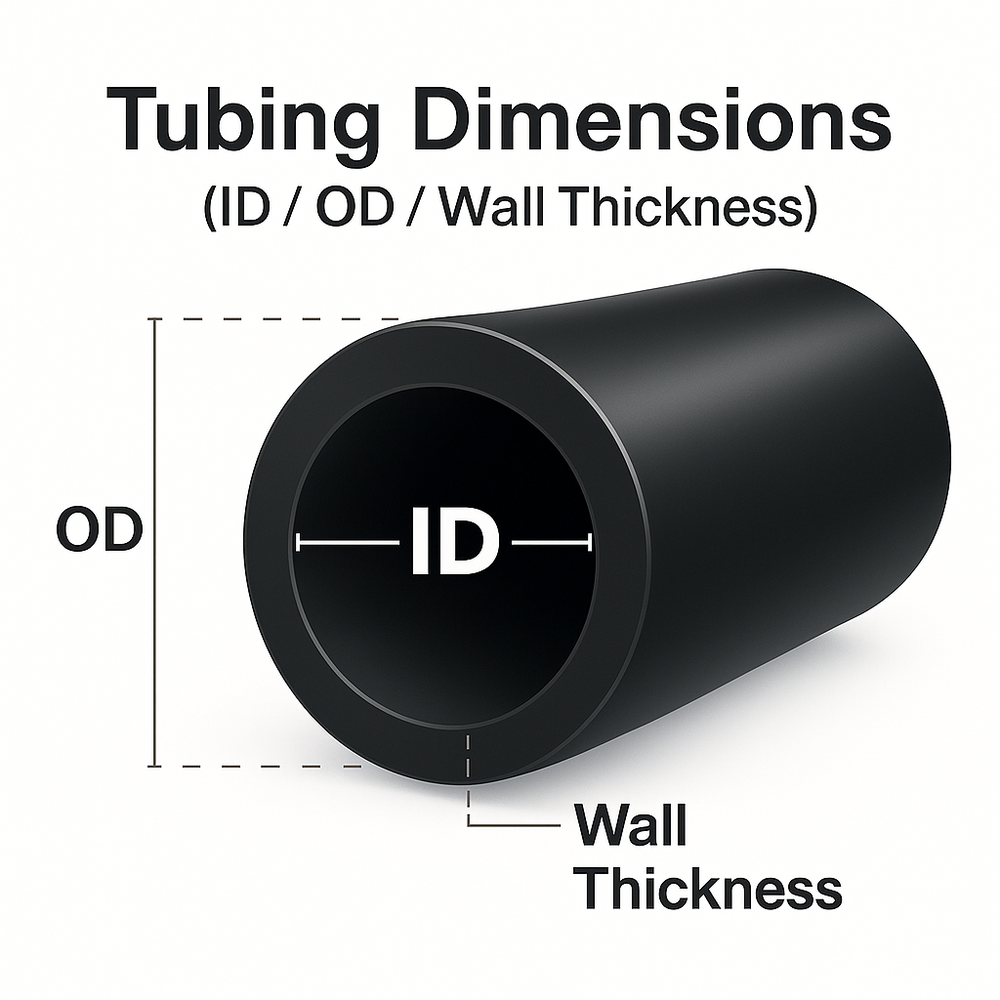

|

Tube OD | Tube ID | Wall Thickness | Weight | Max. Working Pressure 73°F | Min. Burst Pressure 73°F | Min. Bend Radius | Packing Length | Color | |

|---|---|---|---|---|---|---|---|---|---|---|

| +Color | inch | inch | inch | lb/ft | psi | psi | inch | NA | BK | |

| N618091500FT_ | 1/8 | 0.091 | 0.02 | 0.003 | 425 | 1700 | 0.50 | 500ft | □ | ■ |

| N618091100M_ | 100m | |||||||||

| N61809200M_ | 200m | |||||||||

| N618073500FT_ | 1/8 | 0.073 | 0.03 | 0.004 | 625 | 2500 | 0.50 | 500ft | □ | ■ |

| N618073100M_ | 100m | |||||||||

| N618073200M_ | 200m | |||||||||

| N632106500FT_ | 5/32 | 0.106 | 0.03 | 0.005 | 475 | 1900 | 0.60 | 500ft | □ | ■ |

| N632106100M_ | 100m | |||||||||

| N632106200M_ | 200m | |||||||||

| N6316140500FT_ | 3/16 | 0.140 | 0.02 | 0.006 | 300 | 1200 | 1.33 | 500ft | □ | ■ |

| N6316140100M_ | 100m | |||||||||

| N6316140200M_ | 200m | |||||||||

| N6316118500FT_ | 3/16 | 0.118 | 0.03 | 0.009 | 450 | 1800 | 0.80 | 500ft | □ | ■ |

| N6316118100M_ | 100m | |||||||||

| N6316118200M_ | 200m | |||||||||

| N614180250FT_ | 1/4 | 0.180 | 0.04 | 0.012 | 300 | 1200 | 1.30 | 250ft | □ | ■ |

| N614180500FT_ | 500ft | |||||||||

| N614180100M_ | 100m | |||||||||

| N614180200M_ | 200m | |||||||||

| N614170250FT_ | 1/4 | 0.170 | 0.04 | 0.014 | 325 | 1300 | 1.15 | 250ft | □ | ■ |

| N614170500FT_ | 500ft | |||||||||

| N614170100M_ | 100m | |||||||||

| N614170200M_ | 200m | |||||||||

| N6516233250FT_ | 5/16 | 0.233 | 0.04 | 0.017 | 300 | 1200 | 1.58 | 250ft | □ | ■ |

| N6516233500FT_ | 500ft | |||||||||

| N651623350M_ | 50m | |||||||||

| N6516233100M_ | 100m | |||||||||

| N638275250FT_ | 3/8 | 0.275 | 0.05 | 0.025 | 300 | 1200 | 1.75 | 250ft | □ | ■ |

| N638275500FT_ | 500ft | |||||||||

| N63827550M_ | 50m | |||||||||

| N638275100M_ | 100m | |||||||||

| N638250250FT_ | 3/8 | 0.250 | 0.06 | 0.030 | 450 | 1800 | 1.50 | 250ft | □ | ■ |

| N638250500FT_ | 500ft | |||||||||

| N63825050M_ | 50m | |||||||||

| N638250100M_ | 100m | |||||||||

| N612375250FT_ | 1/2 | 0.375 | 0.06 | 0.043 | 300 | 1200 | 2.90 | 250ft | □ | ■ |

| N612375500FT_ | 500ft | |||||||||

| N61237550M_ | 50m | |||||||||

| N612375100M_ | 100m | |||||||||

| N658500250FT_ | 5/8 | 0.500 | 0.06 | 0.056 | 175 | 700 | 5.00 | 250ft | □ | ■ |

| N65850050M_ | 50m | |||||||||

| N658500100M_ | 100m | |||||||||

| N634594250FT_ | 3/4 | 0.594 | 0.08 | 0.081 | 175 | 700 | 8.40 | 250ft | □ | ■ |

| N63459450M_ | 50m | |||||||||

| N634594100M_ | 100m | |||||||||

Metric Size (mm)

|

Part Number

|

Tube OD | Tube ID | Wall Thickness | Weight | Max. Working Pressure 73°F (23°C) | Min. Burst Pressure 73°F (23°C) | Min. Bend Radius | Packing Length | Color | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| +Color | mm | mm | mm | g/m | bar | bar | mm | m | NA | BK | BU |

| N6402525M_ | 4 | 2.5 | 0.75 | 8.8 | 38 | 114 | 30 | 25 | □ | ■ | |

| N6402550M_ | 50 | ||||||||||

| N64025100M_ | 100 | ||||||||||

| N64025200M_ | 200 | ||||||||||

| N6402025M_ | 4 | 2 | 1.00 | 10.8 | 55 | 165 | 25 | 25 | □ | ■ | |

| N6402050M_ | 50 | ||||||||||

| N64020100M_ | 100 | ||||||||||

| N64020200M_ | 200 | ||||||||||

| N6503025M_ | 5 | 3 | 1.00 | 14.4 | 42 | 126 | 30 | 25 | □ | ■ | |

| N6503050M_ | 50 | ||||||||||

| N65030100M_ | 100 | ||||||||||

| N65030200M_ | 200 | ||||||||||

| N6604025M_ | 6 | 4 | 1.00 | 18.1 | 33 | 99 | 45 | 25 | □ | ■ | ■ |

| N6604050M_ | 50 | ||||||||||

| N66040100M_ | 100 | ||||||||||

| N66040200M_ | 200 | ||||||||||

| N6806025M_ | 8 | 6 | 1.00 | 25.3 | 24 | 72 | 65 | 25 | □ | ■ | ■ |

| N6806050M_ | 50 | ||||||||||

| N68060100M_ | 100 | ||||||||||

| N6805525M_ | 8 | 5.5 | 1.25 | 30.5 | 30 | 90 | 60 | 25 | □ | ■ | |

| N6805550M_ | 50 | ||||||||||

| N68055100M_ | 100 | ||||||||||

| N6108025M_ | 10 | 8 | 1.00 | 32.5 | 18 | 54 | 110 | 25 | □ | ■ | |

| N6108050M_ | 50 | ||||||||||

| N61080100M_ | 100 | ||||||||||

| N6107525M_ | 10 | 7.5 | 1.25 | 39.5 | 23 | 69 | 80 | 25 | □ | ■ | |

| N6107550M_ | 50 | ||||||||||

| N61075100M_ | 100 | ||||||||||

| N6107025M_ | 10 | 7 | 1.50 | 46.0 | 29 | 87 | 75 | 25 | □ | ■ | |

| N6107050M_ | 50 | ||||||||||

| N61070100M_ | 100 | ||||||||||

| N6121025M_ | 12 | 10 | 1.00 | 39.7 | 15 | 45 | 165 | 25 | □ | ■ | |

| N6121050M_ | 50 | ||||||||||

| N61210100M_ | 100 | ||||||||||

| N6129025M_ | 12 | 9 | 1.50 | 56.9 | 23 | 69 | 105 | 25 | □ | ■ | |

| N6129050M_ | 50 | ||||||||||

| N61290100M_ | 100 | ||||||||||

| N6141125M_ | 14 | 11 | 1.50 | 67.7 | 20 | 60 | 180 | 25 | □ | ||

| N6141150M_ | 50 | ||||||||||

| N61411100M_ | 100 | ||||||||||

| N6151225M_ | 15 | 12 | 1.50 | 73.1 | 18 | 54 | 170 | 25 | □ | ||

| N6151250M_ | 50 | ||||||||||

| N61512100M_ | 100 | ||||||||||

| N6161325M_ | 16 | 13 | 1.50 | 78.5 | 15 | 45 | 140 | 25 | □ | ||

| N6161350M_ | 50 | ||||||||||

| N61613100M_ | 100 | ||||||||||

| N6181425M_ | 18 | 14 | 2.00 | 115.6 | 19 | 57 | 180 | 25 | □ | ||

| N6181450M_ | 50 | ||||||||||

| N61814100M_ | 100 | ||||||||||

ㆍGood mechanical strength and rigidity for structurally stable piping layouts

ㆍStable chemical compatibility with commonly used industrial oils and media

ㆍConsistent mechanical performance for general industrial pneumatic and fluid systems

ㆍGood abrasion resistance for fixed or limited-movement industrial routing

ㆍPneumatic piping systems for automation equipment

ㆍFluid conveying lines for industrial machinery and control systems

ㆍIndustrial piping systems operating under relatively stable environmental conditions (such as humidity or temperature)