Reinforced Polyurethane Air Hose

※ Click the product image to view more specs and technical details.

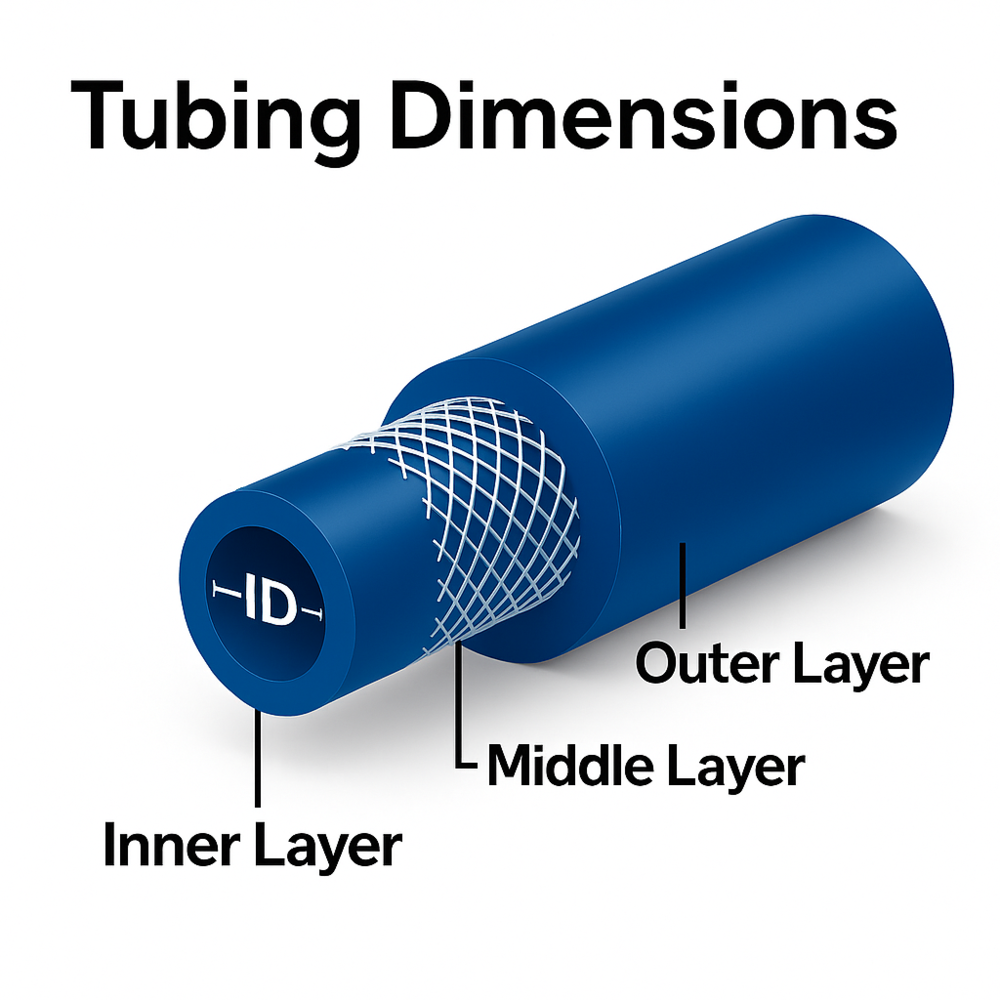

ㆍThree-layer polyurethane braided pneumatic hose

ㆍFiber reinforcement layer for higher working-pressure applications

ㆍStable hose shape under pressure variation

ㆍIndustrial compressed-air piping and air-supply use

ㆍThree-layer polyurethane braided pneumatic hose

ㆍFiber reinforcement layer for higher working-pressure applications

ㆍStable hose shape under pressure variation

ㆍIndustrial compressed-air piping and air-supply use

Model :

UBE

PU braided hose is a three-layer polyurethane pneumatic hose with a fiber reinforcement layer between the inner and outer PU layers. This structure supports higher working-pressure conditions and helps limit diameter expansion under pressure.

It maintains a stable hose profile when pressure varies, reducing localized deformation that may affect routing accuracy and installation stability.

Applies an ether-based polyurethane structure on both inner and outer layers.

Ether-based PU exhibits stable elasticity under humidity and changing operating environments, suitable for on-site pneumatic piping where routing, cutting, and installation are defined by actual system layout.

It maintains a stable hose profile when pressure varies, reducing localized deformation that may affect routing accuracy and installation stability.

Applies an ether-based polyurethane structure on both inner and outer layers.

Ether-based PU exhibits stable elasticity under humidity and changing operating environments, suitable for on-site pneumatic piping where routing, cutting, and installation are defined by actual system layout.

- Available in inch and mm sizes

- Working Pressure : Safety factor 3 to 1

Imperial Size (in)

|

Part Number

|

Tube ID | Tube OD | Wall Thickness | Weight | Max. Working Pressure 73°F | Packing Length | Color | |||

|---|---|---|---|---|---|---|---|---|---|---|

| +Color | inch | inch | inch | lb/ft | psi | ft | T | TBU | TY | R |

| UBE14375100FT_ | 1/4 | 0.375 | 0.06 | 0.030 | 300 | 100 | □ | □ | □ | ■ |

| UBE14375250FT_ | 250 | |||||||||

| UBE14375500FT_ | 500 | |||||||||

| UBE516473100FT_ | 5/16 | 0.473 | 0.08 | 0.050 | 300 | 100 | □ | □ | □ | ■ |

| UBE516473250FT_ | 250 | |||||||||

| UBE516473500FT_ | 500 | |||||||||

| UBE38562100FT_ | 3/8 | 0.562 | 0.09 | 0.069 | 300 | 100 | □ | □ | □ | ■ |

| UBE38562250FT_ | 250 | |||||||||

| UBE38562500FT_ | 500 | |||||||||

| UBE12700100FT_ | 1/2 | 0.700 | 0.10 | 0.094 | 300 | 100 | □ | □ | □ | ■ |

| UBE12700250FT_ | 250 | |||||||||

| UBE12700500FT_ | 500 | |||||||||

Metric Size (mm)

|

Part Number

|

Tube ID | Tube OD | Wall Thickness | Weight | Max. Working Pressure 23°C (73°F) | Packing Length | Color | ||

|---|---|---|---|---|---|---|---|---|---|

| +Color | mm | mm | mm | g/m | bar | m | BU | R | OR |

| UBE651025M_ | 6.5 | 10.0 | 1.75 | 52 | 20 | 25 | ■ | ■ | ■ |

| UBE651050M_ | 50 | ||||||||

| UBE6510100M_ | 100 | ||||||||

| UBE801225M_ | 8.0 | 12.0 | 2.00 | 72 | 20 | 25 | ■ | ■ | ■ |

| UBE801250M_ | 50 | ||||||||

| UBE8012100M_ | 100 | ||||||||

| UBE8512525M_ | 8.5 | 12.5 | 2.00 | 76 | 20 | 25 | ■ | ■ | ■ |

| UBE8512550M_ | 50 | ||||||||

| UBE85125100M_ | 100 | ||||||||

| UBE101425M_ | 10.0 | 14.0 | 2.00 | 87 | 20 | 25 | ■ | ■ | ■ |

| UBE101450M_ | 50 | ||||||||

| UBE1014100M_ | 100 | ||||||||

| UBE111625M_ | 11.0 | 16.0 | 2.50 | 122 | 20 | 25 | ■ | ■ | ■ |

| UBE111650M_ | 50 | ||||||||

| UBE1116100M_ | 100 | ||||||||

・Three-layer braided construction with fiber reinforcement layer

・Working-pressure suitability for industrial pneumatic applications

・Stable hose profile under pressure variation; reduced localized deformation

・Ether-based PU layers; stable elasticity in humid or variable environments

・Suitable for industrial pneumatic piping applications requiring on-site cutting and routing

・Working-pressure suitability for industrial pneumatic applications

・Stable hose profile under pressure variation; reduced localized deformation

・Ether-based PU layers; stable elasticity in humid or variable environments

・Suitable for industrial pneumatic piping applications requiring on-site cutting and routing

・Industrial machinery and equipment pneumatic air lines

・Automation equipment and production-line air supply and distribution

・Pneumatic systems requiring higher working-pressure conditions

・Field-installed pneumatic piping with routing, cutting, and installation on site

・Pneumatic use in environments with variable humidity or operating conditions

・Automation equipment and production-line air supply and distribution

・Pneumatic systems requiring higher working-pressure conditions

・Field-installed pneumatic piping with routing, cutting, and installation on site

・Pneumatic use in environments with variable humidity or operating conditions