SEMICONDUCTOR

Semiconductor Industry Pneumatic Tubing Application Guide

The global semiconductor industry began with the transistor in the 1950s at Bell Labs. Today, it is the core engine powering modern life, from computing and AI to smart manufacturing.

Semiconductor Industry Segmentation and Pneumatic Demand

The semiconductor industry is primarily divided into three major segments:

- Upstream: Focus on High-Purity Gas Distribution and Chemical Handling for critical materials like Silicon Wafers and Photoresist.

- Midstream: Wafer fabrication and Wafer foundry services, such as Taiwan’s leading representative, TSMC.

- Downstream: IC Design, Packaging & Testing, Module Assembly, and End-User Applications.

SHPI Professional Tubing Solutions by Process

- PU Tubing (Polyurethane): Flexible and compact; ideal for wafer dicing, inspection, and AMHS transfer systems.

-

PA12 Tubing (Nylon 12): Strong chemical and corrosion resistance;

used in purification, gas supply, and packaging equipment.

For advanced tools like lithography, etching, or CVD/ALD, SHPI offers anti-static custom options. - PA6 Tubing (Nylon 6): Rigid and pressure-resistant; perfect for pneumatic clamps and automated door systems.

Fitting System — Safe, Simple, Reliable

Use SHPI One Touch Fittings for secure and efficient connections:

- Tube Fittings: Full range, easy to install.

- Speed Controllers: Precise air flow and motion control.

- Check Valves: Prevent backflow, keep pressure steady.

- Hand Valves: Quick air shut-off for service or setup.

- Stop Valves: Auto air seal when disconnected for safe maintenance.

Why Choose SHPI

Choosing SHPI means choosing stability, efficiency, and commitment.

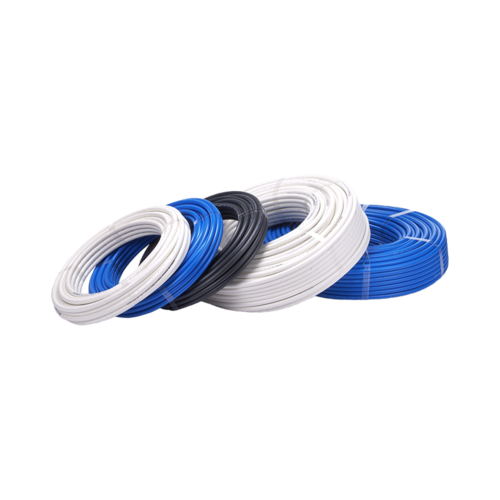

- Wide range of tubing types and colors

- Complete supply of fittings and accessories

- Deep understanding of non-stop production needs

- Fast and reliable replenishment service

Contact us today — let every hose and fitting become the most reliable connection in your semiconductor equipment.

SHPI — The Hose & Tubing Expert

Polyurethane Tubing Ester

.High flexibility; small bending radius

.Accurate dimensions; good sealing

.Smooth surface; resists dust

.Stable performance under repeated flexing

.Good elasticity

.Abrasion resistant

.Multiple colors for easy circuit identification

Polyurethane Tubing Ether

.Excellent hydrolysis resistance

.Good flexibility; stable dynamic bending

.Accurate dimensions; good sealing

.Smooth surface; resists dust

.Abrasion resistant

.Long-term stability; resists yellowing

.Multiple colors for easy circuit identification

Nylon Tubing PA 12

ㆍLow moisture absorption material structure

ㆍGood dimensional stability

ㆍStable chemical compatibility with commonly used industrial oils and media

ㆍConsistent mechanical performance

ㆍGood abrasion resistance

Anti-Spark Tubing

ㆍDual-layer construction: PU inner tubing combined with an outer flame-retardant layer

ㆍOuter layer material classified to UL 94 V-0 flammability rating with self-extinguishing characteristics

ㆍStructural design intended for tubing surface protection in environments involving welding sparks, spatter, and similar operations

ㆍPU tubing maintains the flexibility and dynamic bending stability required for pneumatic routing