Polyurethane Tubing Ester

.High flexibility; small bending radius

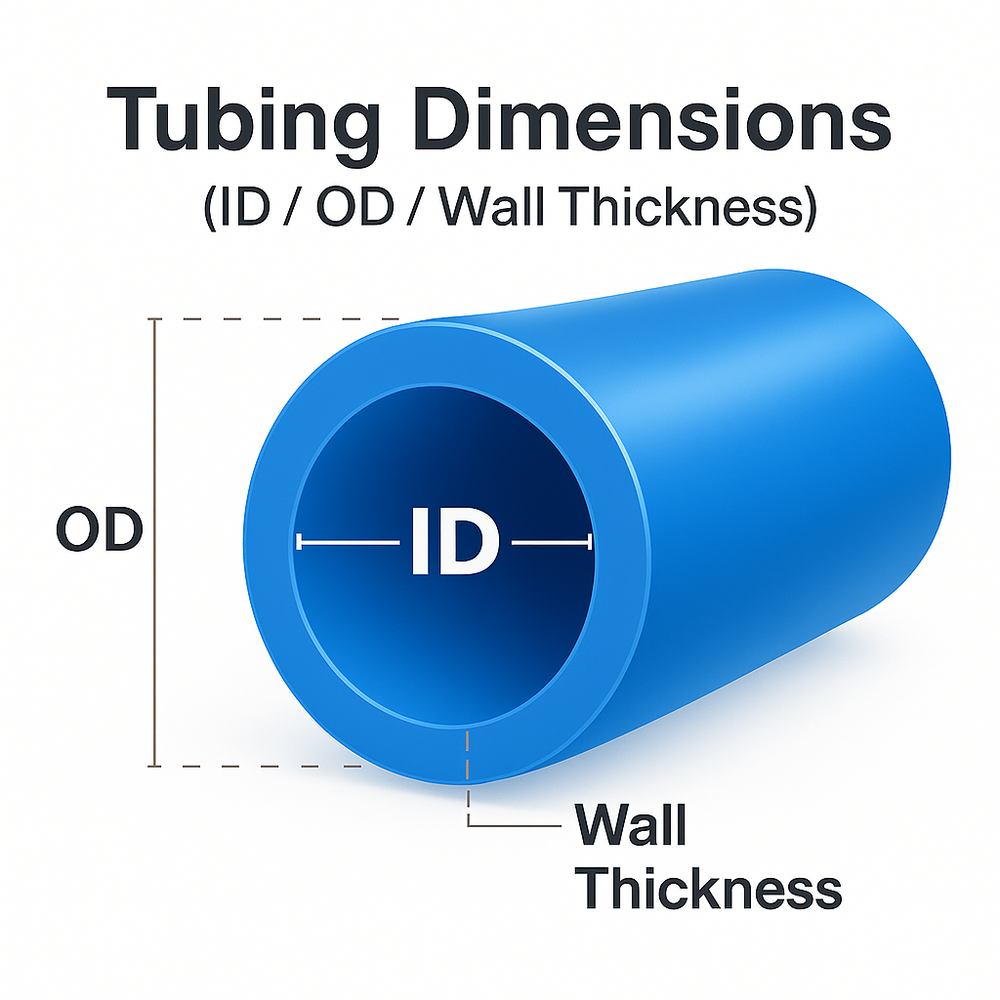

.Accurate dimensions; good sealing

.Smooth surface; resists dust

.Stable performance under repeated flexing

.Good elasticity

.Abrasion resistant

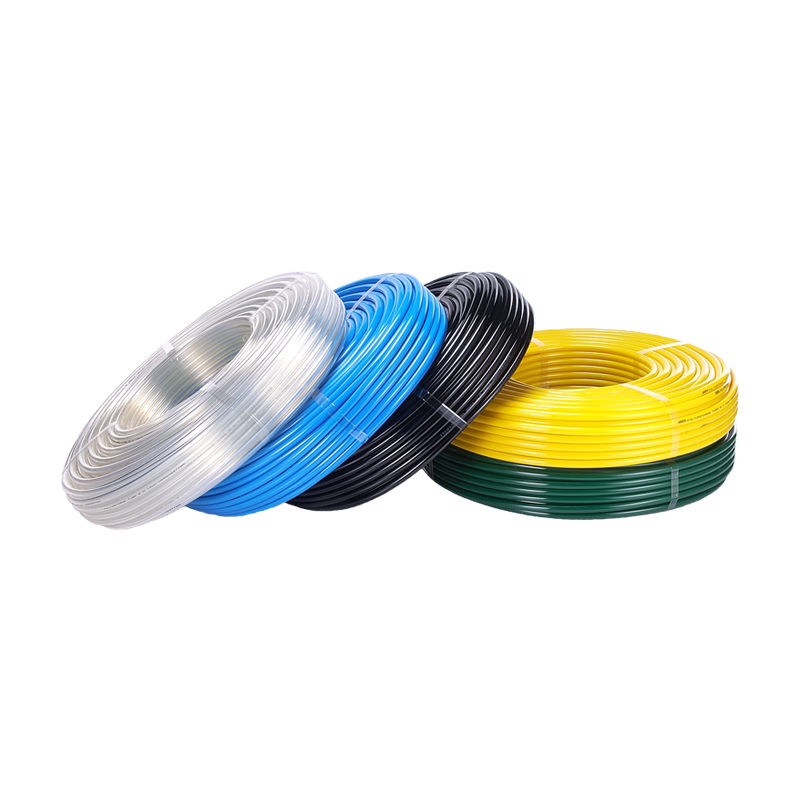

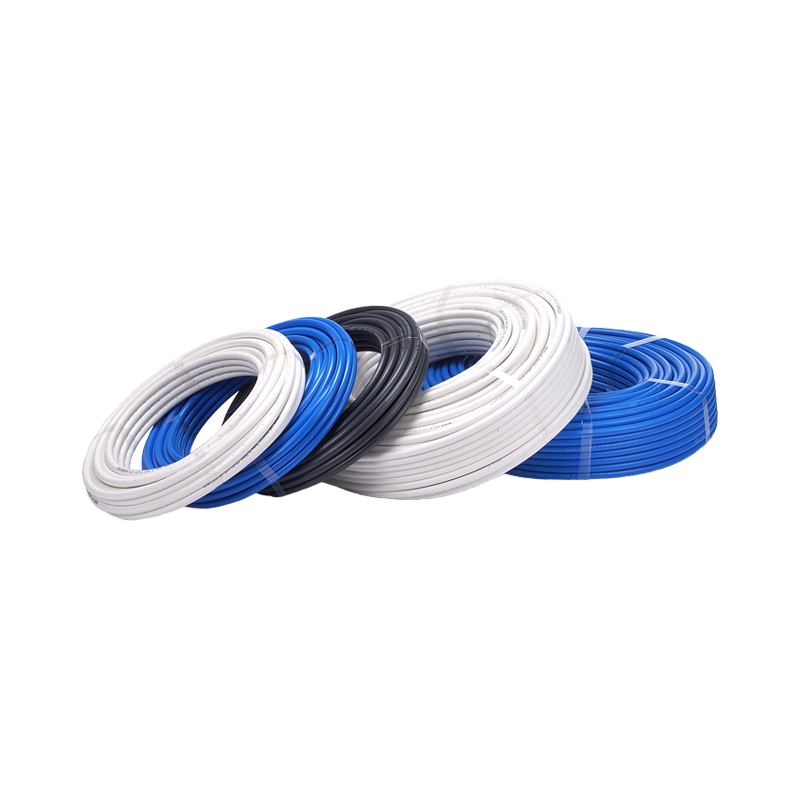

.Multiple colors for easy circuit identification

SHPI PU Ester tubing is designed for pneumatic applications requiring high elasticity, excellent abrasion resistance, and stable performance under repeated flexing.

Its ester-based structure provides good tensile strength and is suitable for general automation and standard industrial pneumatic systems.

Multiple colors are available for easy circuit identification.

Metric Size (mm)

|

Part Number

|

Tube OD | Tube ID | Wall Thickness | Weight | Max. Working Pressure 23°C (73°F) | Min. Burst Pressure 23°C (73°F) | Min. Bend Radius | Packing Length | Color | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| +Color | mm | mm | mm | g/m | bar | bar | mm | m | NA | BK | BU | G | R | Y |

| US301825M_ | 3.0 | 1.8 | 0.60 | 5.6 | 20 | 60 | 10 | 25 | □ | ■ | ||||

| US301850M_ | 50 | |||||||||||||

| US3018100M_ | 100 | |||||||||||||

| US402525M_ | 4.0 | 2.5 | 0.75 | 9.4 | 15 | 45 | 15 | 25 | □ | ■ | ■ | ■ | ■ | ■ |

| US402550M_ | 50 | |||||||||||||

| US4025100M_ | 100 | |||||||||||||

| US402025M_ | 4.0 | 2.0 | 1.00 | 11.6 | 22 | 66 | 15 | 25 | □ | ■ | ■ | ■ | ■ | ■ |

| US402050M_ | 50 | |||||||||||||

| US4020100M_ | 100 | |||||||||||||

| US503025M_ | 5.0 | 3.0 | 1.00 | 15.4 | 16 | 48 | 20 | 25 | □ | ■ | ||||

| US503050M_ | 50 | |||||||||||||

| US5030100M_ | 100 | |||||||||||||

| US604025M_ | 6.0 | 4.0 | 1.00 | 19.3 | 14 | 42 | 25 | 25 | □ | ■ | ■ | ■ | ■ | ■ |

| US604050M_ | 50 | |||||||||||||

| US6040100M_ | 100 | |||||||||||||

| US805025M_ | 8.0 | 5.0 | 1.50 | 37.7 | 15 | 45 | 30 | 25 | □ | ■ | ■ | ■ | ■ | |

| US805050M_ | 50 | |||||||||||||

| US8050100M_ | 100 | |||||||||||||

| US805525M_ | 8.0 | 5.5 | 1.25 | 32.6 | 12 | 36 | 40 | 25 | □ | ■ | ■ | ■ | ■ | |

| US805550M_ | 50 | |||||||||||||

| US8055100M_ | 100 | |||||||||||||

| * US806025M_ | 8.0 | 5.7 | 1.15 | 30.4 | 11 | 33 | 40 | 25 | □ | ■ | ■ | ■ | ■ | ■ |

| * US806050M_ | 50 | |||||||||||||

| * US8060100M_ | 100 | |||||||||||||

| US106525M_ | 10.0 | 6.5 | 1.75 | 55.8 | 14 | 42 | 40 | 25 | □ | ■ | ■ | ■ | ■ | |

| US106550M_ | 50 | |||||||||||||

| US1065100M_ | 100 | |||||||||||||

| US107025M_ | 10.0 | 7.0 | 1.50 | 49.2 | 11 | 33 | 50 | 25 | □ | ■ | ■ | ■ | ■ | |

| US107050M_ | 50 | |||||||||||||

| US1070100M_ | 100 | |||||||||||||

| US107525M_ | 10.0 | 7.5 | 1.25 | 42.2 | 9 | 27 | 60 | 25 | □ | ■ | ■ | ■ | ■ | |

| US107550M_ | 50 | |||||||||||||

| US1075100M_ | 100 | |||||||||||||

| * US108025M_ | 10.0 | 7.7 | 1.15 | 39.3 | 8 | 24 | 65 | 25 | □ | ■ | ■ | ■ | ■ | ■ |

| * US108050M_ | 50 | |||||||||||||

| * US1080100M_ | 100 | |||||||||||||

| US128025M_ | 12.0 | 8.0 | 2.00 | 77.2 | 13 | 39 | 50 | 25 | □ | ■ | ■ | ■ | ■ | |

| US128050M_ | 50 | |||||||||||||

| US1280100M_ | 100 | |||||||||||||

| US129025M_ | 12.0 | 9.0 | 1.50 | 60.8 | 9 | 27 | 70 | 25 | □ | ■ | ■ | ■ | ■ | ■ |

| US129050M_ | 50 | |||||||||||||

| US1290100M_ | 100 | |||||||||||||

| US141025M_ | 14.0 | 10.0 | 2.00 | 92.7 | 11 | 33 | 70 | 25 | □ | ■ | ■ | |||

| US141050M_ | 50 | |||||||||||||

| US1410100M_ | 100 | |||||||||||||

| US141125M_ | 14.0 | 11.0 | 1.50 | 72.4 | 8 | 24 | 100 | 25 | □ | ■ | ■ | |||

| US141150M_ | 50 | |||||||||||||

| US1411100M_ | 100 | |||||||||||||

| US161125M_ | 16.0 | 11.0 | 2.50 | 130.3 | 12 | 36 | 75 | 25 | □ | ■ | ■ | |||

| US161150M_ | 50 | |||||||||||||

| US1611100M_ | 100 | |||||||||||||

| US161225M_ | 16.0 | 12.0 | 2.00 | 108.1 | 9 | 27 | 100 | 25 | □ | ■ | ■ | |||

| US161250M_ | 50 | |||||||||||||

| US1612100M_ | 100 | |||||||||||||

• High flexibility supports tight bending radius routing, suitable for space-constrained or complex tube layouts.

• Stable outer diameter control helps ensure reliable sealing performance and overall system integrity when used with fittings.

• Smooth surface finish helps reduce dust accumulation and maintain clean pneumatic lines.

• Suitable for dynamic pneumatic tubing requiring repeated flexing and movement while maintaining stable performance over time.

• Good elasticity facilitates installation and tube routing adjustments.

• Excellent abrasion resistance, suitable for long-term use.

• Multiple color options for different pneumatic circuit identification and system management.

• General pneumatic tubing systems

• Automation equipment

• Air tools and pick-and-place equipment

• Applications requiring repeated flexing or tight-space tube routing

• Low-temperature environments requiring maintained flexibility