AIR BRAKE SYSTEM

Air Brake Tubing for Heavy-Duty Vehicles – Straight and Coiled Options

Looking for durable, DOT-compliant air brake tubing for commercial or heavy-duty vehicles? Learn the difference between straight and coiled air brake hoses and how to choose the best one for your application.

An air brake system operates by using compressed air to apply pressure to the brake chamber. When the driver presses the brake pedal to stop the vehicle, compressed air is delivered to the brake chamber. This makes the deceleration easier and safer. Air brake systems are widely used in large or heavy-duty vehicles, such as semi-trucks, road trains, trailers and buses. It's a critical and essential feature for high-load vehicles.

Types of Air Brake Tubing: Straight vs Coiled Hose – Installation Guide

The air brake system typically requires two main categories of tubing: straight tubing and coiled air brake hoses.

SHPI offers a full range of air brake tubing and hose solutions compliant with DIN74324 and SAE J844 standards. We recommend confirming your installation requirements and mounting location to select the most suitable product for your application.

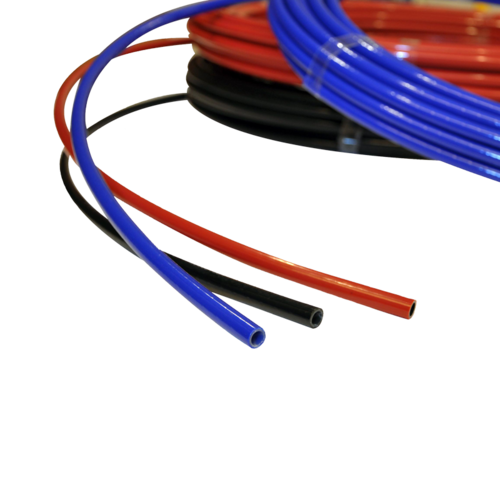

The air brake tubing is primarily installed

along fixed piping routes within the vehicle chassis and the main body –such as

the connections from the air tank to the brake valve, or from the brake valve

to the brake chamber. These locations are generally stationary, not exposed to bending and are not visible

from outside the vehicle.

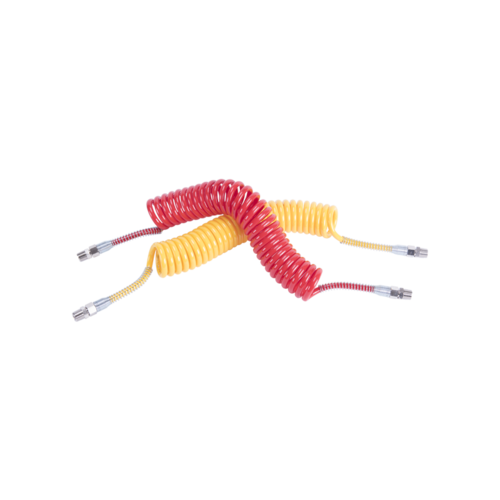

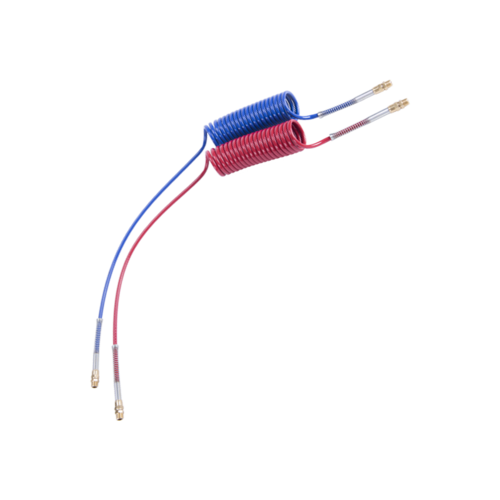

Coiled air brake hoses have a spiral shape and

are installed between the tractor and trailer which is clearly visible on

container trucks.

Their elastic and extendable

properties allow them to adapt to changes in distance caused by turning,

climbing slopes, or movement between connected vehicles.

They are essential for flexible and dynamic brake system connections in high-load vehicle applications.

SHPI Air Brake Tubing products are DOT-compliant and tested for high-pressure applications.

Need Help Choosing the Right Brake Tubing?

We hope the above product overview

helps you select the most suitable air brake tubing or hose for your application.

Whether you need a brake line for commercial trucks or trailers, SHPI has a

trusted solution. Click on the product

category below to explore detailed specifications, features, and product

options.

Air Brake Tubing DIN 74324

・Tubing for pneumatic air brake systems

DOT Air Brake Tubing SAE J844

・Air brake tubing for automotive and commercial vehicle systems

・Designed in accordance with SAE J844 engineering specification (North America)

・DOT FMVSS 571.106 (FMVSS 106) compliant versions available, supported by verified test compliance

Coiled Air Brake Hose Assemblies DIN 74323

・For automotive air brake system use

・Structure and material design aligned with automotive brake system requirements

・Coiled configuration for dynamic use in vehicle brake line routing

・Designed in accordance with DIN 74323 requirements

Coiled Air Brake Hose Assemblies SAE J844

・For automotive air brake system use

・Structure and material design aligned with operating conditions of vehicle brake systems

・Coiled configuration for dynamic use in vehicle brake line routing

・Compliance-oriented versions available based on target market requirements