MACHINE TOOLS

Machine Tool Pneumatic Systems

Modern machine tools are essential to industries like automotive, machinery, metalworking, energy, aerospace, electronics, medical, and defense — with the automotive sector leading in scale and demand. As factories move toward automation and robotics, production becomes safer, faster, and more efficient.

In these precision systems, pneumatic control plays a key role. Stable air pressure keeps machines accurate, responsive, and productive, minimizing downtime.

SHPI offers reliable tubing and fittings built to handle tough industrial environments — keeping your production lines safe, stable, and efficient.

SHPI Tubing — Engineered for Different Machine Environments

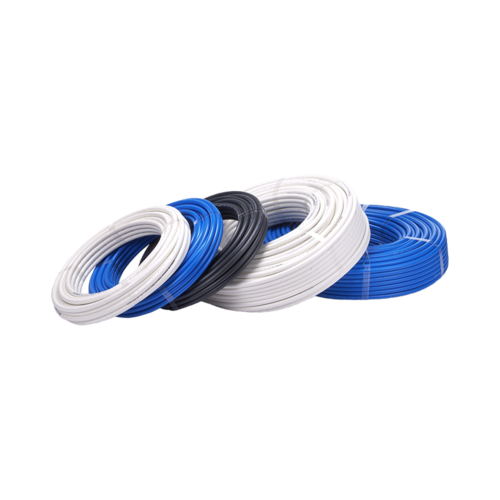

We offer a full range of high-quality pneumatic tubing for machine tool applications:

- Polyurethane Tubing – Flexible and durable; ideal for lathes, milling, and drilling with frequent motion.

- Nylon 6 Tubing (PA6)– Rigid and strong; perfect for drilling or grinding machines needing stability.

- Nylon 12 Tubing (PA12) – Wear- and chemical-resistant; a reliable choice for machining and gear systems.

- Anti-Spark Tubing – UL94 V-0 rated; protects operators and equipment in welding or spark-prone areas.

The Perfect Match — Double the Efficiency

SHPI One Touch Fittings use a push-to-connect design that speeds up assembly and maintenance. Along with standard types, we offer options for enhanced system control:

- Hand Valves – Quick air on/off control for setup or service.

- Check Valves – Prevent backflow, protecting cylinders and regulators.

- Stop Valves – Shut off air automatically when disconnected for safer maintenance.

More Functional Tubing Options

- High-Pressure Use: Reinforced Polyurethane Air Hoses and Hybrid Air Hoses feature a 3-layer design rated to 300 PSI, ideal for long or high-pressure air lines.

- Flexible Setup: Coiled hoses (PU / Nylon 12) save space and extend easily for mobile or workstation setups.

Why Choose SHPI

Choosing SHPI means choosing stability, efficiency, and reliability.

- Quality You Can Trace

- Complete Pneumatic Solutions

- 40+ Years of B2B Manufacturing Experience

- Custom Made for You (OEM / ODM)

- Always On Your Side

Contact SHPI today to get the most reliable pneumatic solutions for your machine tool system.

SHPI – The Hose & Tubing Expert

Polyurethane Tubing Ester

.High flexibility; small bending radius

.Accurate dimensions; good sealing

.Smooth surface; resists dust

.Stable performance under repeated flexing

.Good elasticity

.Abrasion resistant

.Multiple colors for easy circuit identification

Polyurethane Tubing Ether

.Excellent hydrolysis resistance

.Good flexibility; stable dynamic bending

.Accurate dimensions; good sealing

.Smooth surface; resists dust

.Abrasion resistant

.Long-term stability; resists yellowing

.Multiple colors for easy circuit identification

Nylon 12 Tubing (PA12)

ㆍLow moisture absorption material structure

ㆍGood dimensional stability

ㆍStable chemical compatibility with commonly used industrial oils and media

ㆍConsistent mechanical performance

ㆍGood abrasion resistance

Nylon 6 Tubing (PA6)

ㆍGood mechanical strength and rigidity

ㆍStable chemical compatibility with commonly used industrial oils and media

ㆍConsistent mechanical performance

ㆍGood abrasion resistance

Anti-Spark Tubing

ㆍDual-layer construction: PU inner tubing combined with an outer flame-retardant layer

ㆍOuter layer material classified to UL 94 V-0 flammability rating with self-extinguishing characteristics

ㆍStructural design intended for tubing surface protection in environments involving welding sparks, spatter, and similar operations

ㆍPU tubing maintains the flexibility and dynamic bending stability required for pneumatic routing

Reinforced Polyurethane Air Hose

ㆍThree-layer polyurethane braided pneumatic hose

ㆍFiber reinforcement layer for higher working-pressure applications

ㆍStable hose shape under pressure variation

ㆍIndustrial compressed-air piping and air-supply use

Reinforced Polyurethane Air Hose Assemblies

ㆍAssembled three-layer polyurethane braided pneumatic hose

ㆍFiber-reinforced structure for pneumatic piping applications requiring higher working pressure

ㆍStable hose geometry under pressure variation

ㆍIndustrial compressed-air piping and air-supply use